The Ultimate Guide to 3D Printing: From Basics to Advanced Techniques

Introduction to 3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that allows you to create three-dimensional objects from digital models. This technology has transformed various industries by making it easier to prototype, manufacture, and customize products.

In this guide, we’ll explore everything you need to know about 3D printing, from the basic principles and technologies to advanced techniques and real-world applications.

Understanding 3D Printing Technologies

3D printing technologies vary in their approach and applications. The most common types include:

Fused Deposition Modeling (FDM)

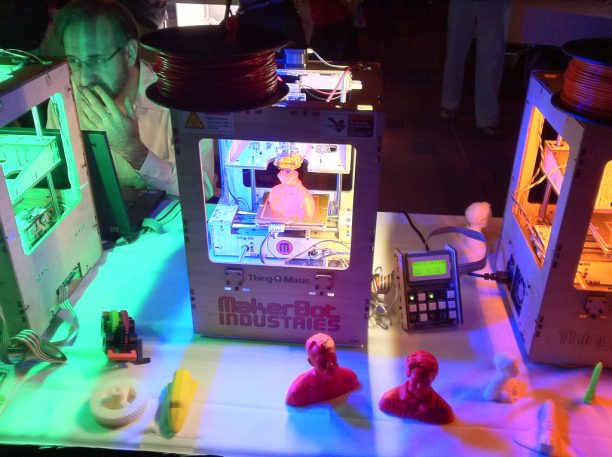

FDM is the most widely used 3D printing technology. It works by melting and extruding filament material layer by layer to build the object. FDM printers are known for their affordability and ease of use.

Learn more about FDM on Wikipedia

Stereolithography (SLA)

SLA uses a laser to cure liquid resin into solid layers. This method produces high-resolution prints with fine details, making it ideal for intricate designs and professional applications.

Learn more about SLA on Wikipedia

Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered material into solid structures. It is well-suited for producing complex geometries and durable parts, often used in industrial applications.

Learn more about SLS on Wikipedia

Other Technologies

There are other specialized 3D printing technologies like Digital Light Processing (DLP), MultiJet Printing (MJP), and more. Each has its unique advantages and applications.

Components of a 3D Printer

Understanding the fundamental components of a 3D printer helps in choosing the right machine and troubleshooting issues:

Extruder

The extruder is responsible for feeding and melting the filament in FDM printers. It includes the hotend and the drive mechanism.

Build Plate

The build plate is where the object is printed. It may be heated to help with adhesion and prevent warping.

Frame

The frame holds all the components together. It affects the stability and precision of the printer.

Stepper Motors

Stepper motors control the movement of the print head and build plate, enabling accurate layer deposition.

Choosing the Right 3D Printer

Selecting the right 3D printer depends on various factors, including budget, precision, and the materials you’ll use.

Budget

For hobbyists and beginners, budget-friendly FDM printers are a great choice. For professional use, SLA and SLS printers offer higher precision and better material options.

Precision

If you need high-resolution prints, look for SLA or DLP printers. For larger, less detailed prints, FDM printers will suffice.

Materials

Consider what materials you plan to print with. FDM printers handle PLA and ABS well, while SLA printers work with various resins.

3D Printing Materials

Different 3D printing technologies use various materials. Here are some commonly used ones:

PLA (Polylactic Acid)

PLA is a biodegradable and easy-to-use filament, ideal for beginners and general-purpose printing.

ABS (Acrylonitrile Butadiene Styrene)

ABS is known for its strength and durability. It is often used in functional parts and prototypes.

Resin

Resins are used in SLA and DLP printers. They offer high precision and are available in various types, including standard, tough, and flexible resins.

Specialized Filaments

Specialized filaments include materials like TPU (Thermoplastic Polyurethane) for flexibility, and composite filaments like carbon fiber-infused PLA for strength.

Useful Links

Software for 3D Printing

Software plays a crucial role in 3D printing. It includes CAD programs for designing models and slicing software for preparing files for printing.

CAD Software

CAD (Computer-Aided Design) software is used to create 3D models. Popular options include:

Slicing Software

Slicing software converts 3D models into instructions for 3D printers. Key settings include:

- Layer Height: Determines the thickness of each layer.

- Infill: The density of the internal structure of the print.

- Supports: Structures added to support overhangs during printing.

Popular slicing software includes:

Useful Links

- Best CAD Software for 3D Modeling

- Best Slicing Software for 3D Printing

Advanced 3D Printing Techniques

For advanced users, exploring sophisticated techniques can lead to high-quality prints and new possibilities.

Multi-Material Printing

Multi-material printing allows you to use different filaments in a single print, adding complexity and functionality. This requires a compatible printer and careful setup.

Post-Processing Techniques

Post-processing enhances the appearance and properties of printed objects:

- Sanding: Smoothens the surface.

- Painting: Adds color and finish.

- Vapor Smoothing: Uses solvents to improve surface quality.

Troubleshooting Common Issues

Common printing issues include:

- Warping: Caused by uneven cooling. Use a heated bed or enclosure.

- Stringing: Fine threads of filament left between parts. Adjust retraction settings.

- Layer Shifts: Misalignment of layers. Check the printer’s mechanics and calibration.

Useful Links

- Advanced 3D Printing Tips

- Tips for Multi-Material 3D Printing

Mastering 3D Printing

Mastering 3D printing involves learning to design complex models, understanding the technology’s limitations, and exploring its potential applications.

Designing Complex Models

Advanced design involves creating intricate models and understanding how to optimize them for printing. Practice with CAD software and study successful designs.

Applications of 3D Printing

3D printing is used in various fields:

- Healthcare: Custom prosthetics and implants.

- Automotive: Prototype parts and tooling.

- Consumer Products: Customizable products and accessories.

Real-World Examples

Notable 3D printing applications include: